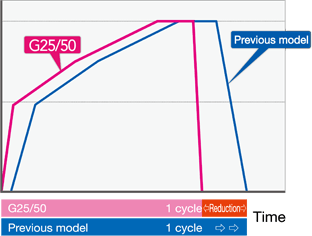

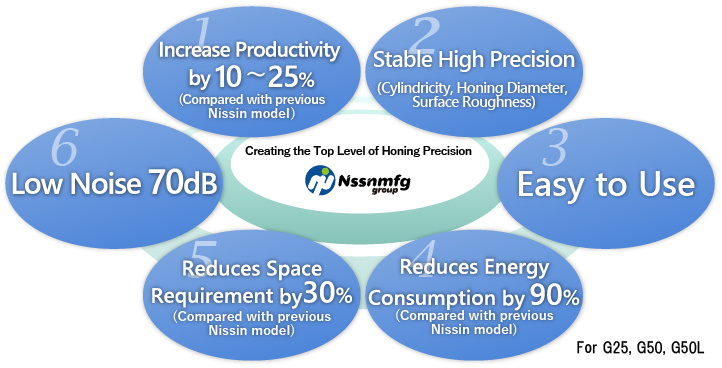

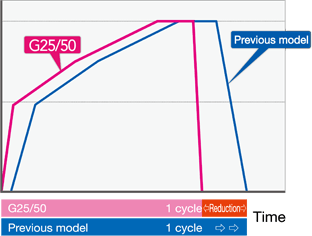

1. Offers a 10 to 25% enhancement in productivity (compared with previous models)

- Higher speeds reduce processing time.

General purpose models that offers ease of use at a reasonable price

The G series line of honing machines utilize an innovative servo-controlled mechanism for expanding the grinding stones to produce innovative products. By making precise and minute cuts that are synchronized with the spindle stroke, the G series not only improves surface roughness, but also enables ultra-precise machining. It achieves this by correcting the forms of precision zones and ensuring consistent bore diameters, even when dealing with mass-produced parts.

High-precision processing is achieved through synchronized stone expansion, leading to consistent precision, accuracy, and surface roughness as stone expansion is also in synchronization with the spindle stroke.

Onscreen display of sequence programs and manuals.

Automatic adjustment of stone expansion.

A 90% reduction in power consumption (compared with previous models).

Annual cost savings of ¥140,000.

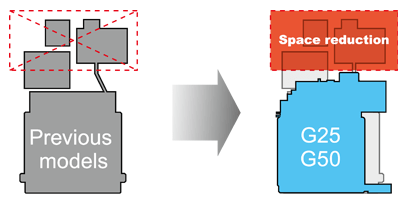

Size reductions achieved by eliminating hydraulic systems.

Quiet operation due to servo motor-drive.

A mid-sized honing machine inheriting the technology cultivated from our experience in small-bore honing machines.

Details

The G25/G50 type offers comprehensive functionality for improved workability, coupled with improved productivity and reduced energy consumption.

Details

The G50L type comprises of a long stroke type of the G50 type.

Details

This type has a small-footprint and its modular cell design offers the freedom to easily combine and configure cells to match production needs.

Details

Nissin ProSOL’s comprehensive catalogue and other resources are available for download.

If you have any questions or inquiries, please feel free to use the form below to get in touch with us.

NISSIN ProSOL CO., LTD. Sales Department

85 Akasaka, Mineyama-cho, Kyotango, Kyoto, 627-0006, JAPAN

Tel. +81-772-62-8088(Rep.) Fax. +81-772-62-6688

Copyright NISSIN ProSOL CO., LTD. All Rights Reserved.