Overview

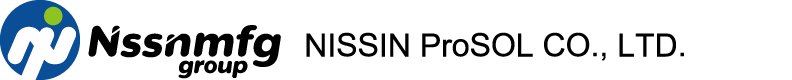

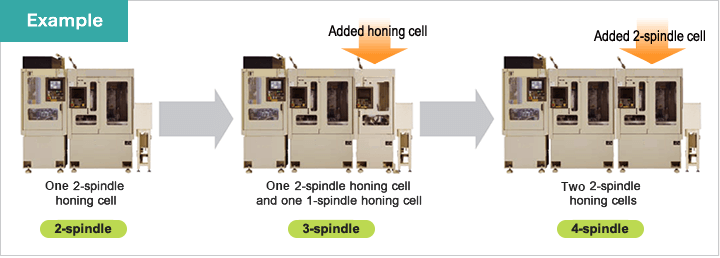

Three Cell Types Allow for Various Configurations

F25G/F50G honing cells can be combined in various configurations. Space-saving installation and adaptable cell-combination provides the flexibility to add or remove cells after initial installation allowing for flexible add/remove after machine delivery, and easy conversion boosting productivity. In such a way, these honing cells offer an unconventional solution.