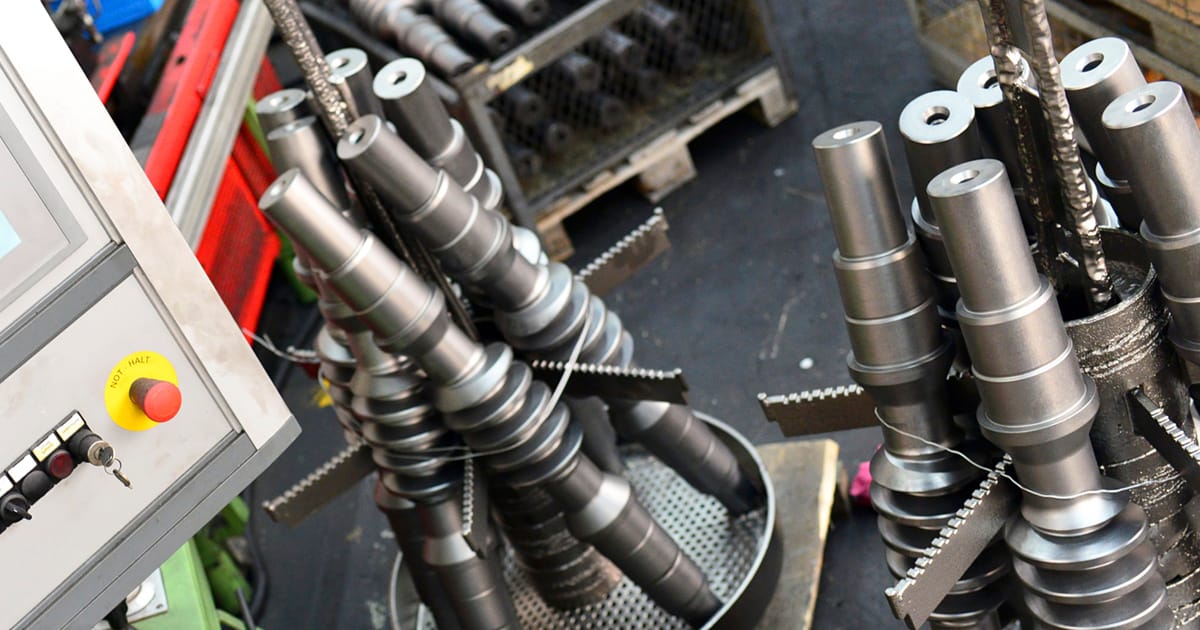

Industry:Hydraulic component manufacture

Department:Production engineering division

Comprehensive support backed up by extensive experience was key to decision to implement specialized machining solution

Switching to honing machines from NISSIN ProSOL reduced internal bore finishing times by up to 30%.

The use of a honing solution for internal bore finishing resulted in consistent axial straightness, hole diameter, and surface finish.

Linking the system to cameras and a slide table enabled the centering process to be fine-tuned, thereby eliminating misalignment.

The supplier had access to comprehensive customer support, including pre-installation consultation and after sales service.

The employee and the rest of the production engineering team actively gathered and compared information on internal bore finishing solutions at trade fairs. Many members of the team felt that NISSIN ProSOL, which offered comprehensive customer support that consisted of everything from processing testing before purchase, right through to machine rental, and even contracted honing services, was the right company to solve their problems. The team decided to make enquiries with NISSIN ProSOL, and commission test bores so they could evaluate the machines’ performance.

“NISSIN ProSOL’s experienced team gave us extensive support and advice even before we had purchased the machines. As the results of the processing testing showed that a honing solution would ensure consistent straightness, hole diameter and surface roughness, we began seriously considering this option,” says the employee.

The supplier subsequently decided to purchase the G50 L-MS1 honing machine and switched its internal bore finishing process to a honing-based one.

The semiautomatic G50 L-MS1 features a slide table, which is combined with sensors that measure the diameter of machined holes and automatically perform adjustments, ensures consistent hole diameter. To dispel the supplier’s concerns about misalignment, NISSIN ProSOL also suggested measuring component coordinates and using the slide table to perform corrections, thereby enabling the component centering process to be fine-tuned.

“We were able to slash time spent on internal bore finishing by up to 30%, and machining was consistently accurate, leading to improved yields and cost price. I believe the improvement in hole diameter precision resulting from automatic adjustments performed by the measurement system was particularly significant. The more precise centering of workpieces thanks to the use of cameras to verify coordinates and slide tables to made fine adjustments, means components are no longer misaligned. At last, nothing is holding our performance back,” reflects the employee.

Since installing the G50 L-MS1, the supplier has continued to receive useful advice and proposals from NISSIN ProSOL regarding jigs, tools, and machining parameters, and is satisfied with NISSIN ProSOL’s after-sales service. The supplier hopes to maintain a good relationship with NISSIN ProSOL in future.

Nissin ProSOL’s comprehensive catalogue and other resources are available for download.

If you have any questions or inquiries, please feel free to use the form below to get in touch with us.

NISSIN ProSOL CO., LTD. Sales Department

85 Akasaka, Mineyama-cho, Kyotango, Kyoto, 627-0006, JAPAN

Tel. +81-772-62-8088(Rep.) Fax. +81-772-62-6688

Copyright NISSIN ProSOL CO., LTD. All Rights Reserved.