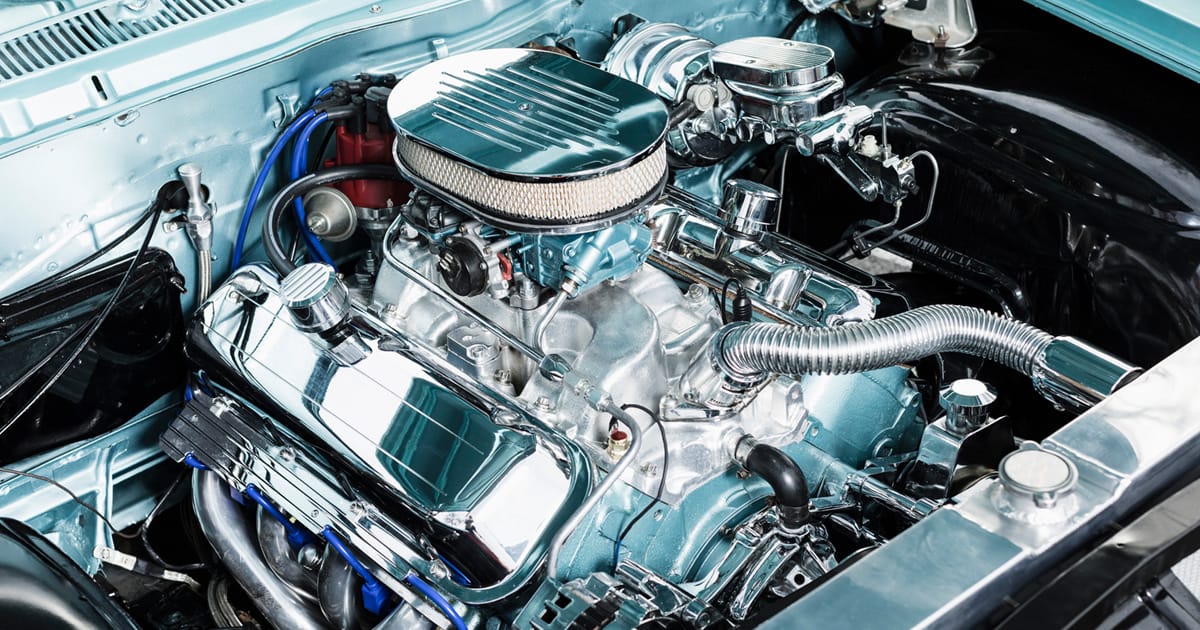

Industry:Manufacturer of automotive components

Department:Production engineering division

New Tools Boost Precision and Productivity

The manufacturer featured in this case study produces 20,000 components every month for use in internal combustion engines. Amid increasing competition, the manufacturer wanted to set itself apart from its competitors with the internal bore finishing process that it excelled at. However, new components were prone to reduced yields, that made it necessary to implement urgent improvements.

The manufacturer finished internal bores of new components using older dual-spindle, index table honing machines. However, because the specifications of these new components called for higher accuracy than those of other components, execution of squareness on the older honing machines was inconsistent, and yield suffered. It was also necessary to center two jigs when changing the set-up, but the process was heavily reliant on the intuition and skill of experienced operators, and was therefore difficult to pass on to more junior operators making it hard for those junior operators to acquire these skills.

An employee from the production engineering division looked back on the troubles at the time as follows:

“The existing setup had reached its limits in terms of production capacity, but we had to do everything we could to prevent further yield declines. At the same time, those on the factory were going flat out trying to produce and ship components in sufficient quantities, so experienced operators did not have as much time to pass on their skills as we had hoped.”

The employee, along with all the rest of the production engineering team, discussed how the production arrangements could be improved. However, as time passed, the team failed to come up with an appropriate solution. The employee began to get anxious.

New components suffered from poor yields when processed on older honing machines.

Centering adjustment of jigs was dependent on the intuition and skill of experienced operators.

Busy meeting production targets, operators were unable to pass down their skills to junior employees.

Nissin ProSOL’s comprehensive catalogue and other resources are available for download.

If you have any questions or inquiries, please feel free to use the form below to get in touch with us.

NISSIN ProSOL CO., LTD. Sales Department

85 Akasaka, Mineyama-cho, Kyotango, Kyoto, 627-0006, JAPAN

Tel. +81-772-62-8088(Rep.) Fax. +81-772-62-6688

Copyright NISSIN ProSOL CO., LTD. All Rights Reserved.